Free delivery. Terms and Conditions apply.

When it comes to running a successful business in Singapore’s food and beverage (F&B) sector, floral supply industry, or restaurant operations, choosing the right refrigeration unit is more than just a matter of storage—it’s a decision that directly affects food quality, customer satisfaction, and energy consumption.

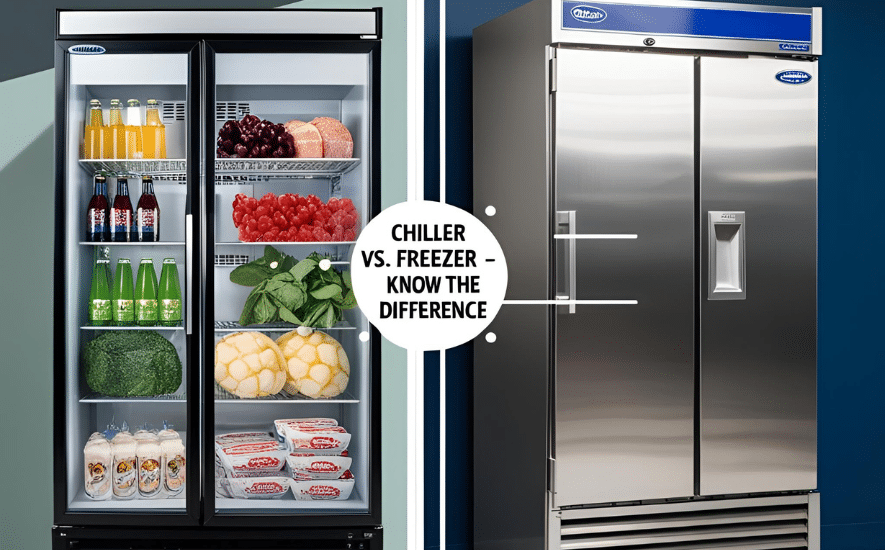

Business owners often face this common question: should I get a chiller or a freezer? Though both are essential appliances in commercial environments, their use cases, temperature settings, structure, and energy needs vary significantly.

Understanding the nuances between a chiller and a freezer is crucial. Whether you’re food at a convenience store, storing raw seafood in a hawker stall, or chilling desserts in a central kitchen, the type of refrigeration you choose impacts your day-to-day operations.

In this comprehensive guide, we’ll unpack everything you need to know about chillers and freezers—from basic definitions to internal components, types, differences, pros and cons, and how to make the best decision for your business.

A chiller refrigerator is a cooling unit designed to maintain a controlled, above-freezing temperature—typically between 0°C to 8°C—ideal for storing perishable items that require cold, but not frozen, environments. In a commercial setting, chillers are crucial for extending the shelf life of fresh food products like dairy, beverages, pre-prepared meals, fruits, vegetables, or even flowers.

Unlike freezers, which hard-freeze products to halt bacterial growth entirely, chillers slow down the activity of microorganisms without turning water content into ice. This makes chillers perfect for daily-use items that need to remain fresh and accessible but not frozen solid.

You might be wondering—what exactly makes a chiller work?

At its core, a commercial chiller contains several key components:

Compressor – The heart of the chiller. It compresses refrigerant gas and pushes it through the refrigeration system.

Condenser – Typically located at the back or top, it dissipates heat from the refrigerant, turning it into a liquid.

Expansion Valve – Regulates refrigerant flow into the evaporator.

Evaporator – Absorbs heat from inside the fridge and cools down the stored items.

Refrigerant – The cooling agent that circulates through the above components to absorb and expel heat.

Many upright and undercounter chiller models also include fans, digital thermostats, and adjustable shelving for better cooling distribution and ease of use.

Depending on your business size, floor space, and storage needs, chillers come in different forms. Here’s a look at the most common types found in Singapore’s commercial landscape:

Upright Chiller – Tall, slim, and typically placed in kitchens or storage areas. Ideal for beverages, dairy, and prepped food in hotels, boarding schools, and restaurants.

Undercounter Chiller – Compact and often installed beneath worktables. Perfect for bars, cafés, and small restaurants where space is a premium.

Display Chiller – Comes with glass doors and is meant for customer-facing areas like bakeries and supermarkets. Ideal for showcasing cakes, drinks, and desserts in small kitchens or bars.

Cake Display Chiller – These are mainly focused on keeping cakes and bakery items fresh. Ideal for small bakery and pastry shops.

Island Chiller – Keeps cooking items like vegetables, meat, and grocery items fresh. Island display chillers are used in supermarkets, and convenience stores.

Each type of chiller can store a specific category of items—from cooked meats and deli items to beverages, dairy, floral bouquets, and even pharmaceuticals—depending on temperature consistency and humidity levels.

A freezer refrigerator, commonly known simply as a freezer, is a refrigeration unit designed to maintain temperatures below 0°C, typically between -10°C and -25°C, depending on the model and application. The primary function of a freezer is to preserve food and other perishables by freezing the water content within, effectively halting bacterial growth and enzymatic activity.

In commercial settings across Singapore—from seafood distributors to restaurant kitchens and central catering facilities—freezers play a vital role in storing bulk meats, frozen vegetables, ice cream, and even semi-prepared meals.

Freezers are essential for businesses that need to store items long-term, reduce spoilage, and maintain a consistent inventory of frozen goods, especially in environments with fluctuating demand.

While chillers and freezers share similar basic technologies, freezers are built to operate at much lower temperatures and require more robust insulation and freezing power.

Here are the key components that make a freezer functional:

High-Performance Compressor – Designed to operate efficiently at low temperatures over extended periods.

Thicker Insulation Panels – Keeps cold air trapped inside, reducing energy usage and preventing temperature fluctuation.

Evaporator Coil – Absorbs heat from inside the freezer and helps lower the internal temperature.

Refrigerant – Often different from chiller units, it’s engineered to handle sub-zero heat exchange.

Condenser Unit – Works in tandem with the compressor to expel heat.

Defrost Mechanism – Prevents ice buildup, which is common in freezers due to moisture condensation.

Temperature Controller or Digital Thermostat – Allows businesses to precisely control internal temperatures, critical for regulatory compliance and food safety.

Freezers, like chillers, are available in a wide variety of models and configurations, each tailored for different business needs and floor plans:

Chest Freezer – A horizontal freezer with a flip-top lid. These are ideal for storing bulk meat, frozen produce, and seafood in hawker stalls, catering companies, or minimarts. Known for energy efficiency and capacity.

Upright Freezer – Vertical, cabinet-style design with shelves. Good for organized storage in restaurants and medical labs.

Undercounter Freezer – Compact and designed for kitchens where space is limited. Common in cafes and F&B prep stations.

Deep Freezer – A term often used interchangeably with chest freezers, but typically indicates even lower temperature thresholds. Useful for long-term storage.

Garage-Ready Freezer – These are built to handle Singapore’s ambient temperature changes, even in non-airconditioned storerooms or delivery hubs.

Each type serves a unique storage function—bulk meat, frozen desserts, backup inventory for off-peak periods—and caters to different operational needs across Singapore’s foodservice, retail, and hospitality sectors.

The differences between chiller and freezer are more than just cold vs. frozen—they affect everything from how long products last to how much electricity your business consumes. For Singapore’s F&B businesses, florists, and restaurant operators, understanding these differences is essential to maintaining food safety, efficiency, and cost control.

Let’s break this down in detail:

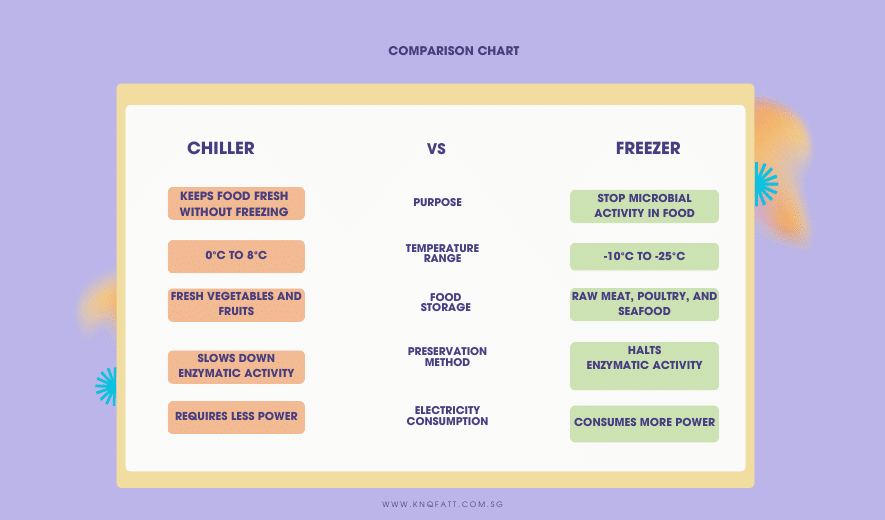

Chillers and freezers serve distinctly different roles in a commercial environment.

In short, if your business needs fast access to fresh products, a chiller is the go-to. If you need long-term storage, the freezer takes the crown.

For example, a Singaporean bakery might use a display chiller for freshly baked cakes but rely on a deep freezer to store frozen dough.

The most straightforward technical difference lies in the temperature range:

This variance in temperature also affects how you arrange stock, how often you can open the door, and how long food lasts. Chillers support frequent access with minimal condensation issues. Freezers, on the other hand, need you to manage frost buildup and defrost cycles.

Both chillers and freezers come in similar sizes—upright, undercounter, display, or walk-in—but the internal usable capacity differs.

Additionally, accessibility matters:

The preservation method is another core difference:

For Singaporean businesses, especially those managing freshly made food or high-turnover perishables, chillers offer the flexibility of rotation and ready-to-serve convenience. Freezers work better for inventory control, backup supply, and reducing food waste over time.

When it comes to electricity consumption, the general assumption is that freezers use more energy. And it’s mostly true—but context matters.

However, placement and usage also matter. A poorly ventilated undercounter freezer might work harder (and use more electricity) than a well-maintained upright chiller placed in a cool area.

Another factor is the type of product stored. For instance, blast chillers vs. commercial freezers may use similar power in short bursts, but their purposes and efficiency profiles differ greatly.

That’s why it’s crucial to consider real-world energy efficiency, not just theoretical ratings, when choosing a unit.

Walk-In Chillers: Maintain 0–5°C for short-term storage of fresh produce or floral stock. Used in restaurants for daily ingredient access.

Walk-In Freezers: Operate at -18°C or lower, ideal for bulk storage in catering businesses or seafood wholesalers.

Choosing between a chiller and a freezer isn’t just about picking cold or colder—it’s about balancing operational needs, energy costs, product lifespan, and daily workflow. Here’s a closer look at the pros and cons of each unit to help business owners in Singapore make an informed decision.

Of course, each unit has its limitations:

This leads us to the final consideration: how do you choose what’s right for your business? That depends on your product mix, inventory turnover rate, and how much space you have available.

You can also choose a combined chiller-freezer unit, if your business demands so. There are some differences between combined refrigerators and separate units. Always consider your business needs before deciding.

Choosing between a chiller and a freezer is one of the most important decisions a Singaporean business owner can make—especially in industries like F&B, floral retail, catering, or hospitality. But once you’ve made the choice, finding a reliable, affordable, and expert-backed supplier is just as crucial.

At KnQ Fatt Refrigeration, we make that part simple.

We provide a wide range of commercial refrigeration units—from upright chillers to chest freezers, undercounter models to walk-in cold rooms—tailored to your specific business needs. Whether you’re looking to store flower bouquets at optimal humidity, keep sashimi chilled at precise temperatures, or store a month’s worth of frozen supplies—we have the right unit for you.

But that’s not all.

We also offer:

If you’re ever unsure whether a chiller or freezer is the better fit—or whether you need both—we’re always happy to provide expert advice, grounded in years of experience serving local restaurants, florists, hotels, and industrial kitchens.

Your refrigeration system is not just a piece of equipment—it’s a critical part of your business. With KnQ Fatt, you get more than just hardware. You get peace of mind, ongoing support, and a long-term partner in growth.

In Singapore’s food and beverage industry, commercial refrigerators play a crucial role in maintaining food safety, freshness, and compliance with local regulations. A minor cooling issue or faulty seal can quickly turn into a costly problem — leading to product spoilage, downtime, and even non-compliance with Singapore Food Agency (SFA)

A malfunctioning commercial refrigerator can disrupt operations, compromise food safety, and lead to costly inventory losses—especially in Singapore’s heat and humidity. Whether you’re noticing unusual noises, fluctuating temperatures, or excessive frost buildup, knowing the warning signs of refrigerator failure is essential. In this guide, we break down everything you need

Whether you’re running a busy hawker kitchen, managing a cold display in a convenience store, or operating a central kitchen in Changi, your commercial refrigerator is one of your most valuable assets. When maintained properly, it preserves food safety, ensures energy efficiency, and keeps operations running smoothly. But in Singapore’s

Commercial refrigerators are essential for businesses in the food, medical, and retail industries, ensuring that perishable goods remain fresh and safe. However, maintaining the right temperature is crucial for food safety, energy efficiency, and equipment longevity. In this guide, we’ll cover ideal temperature settings, how to maintain them, common temperature

Choosing the right commercial freezer can make a significant impact on your business operations—whether you’re running a busy restaurant in Bugis, managing a 24-hour convenience store in Bedok, or stocking up perishables for your catering service in Jurong. In Singapore’s competitive F&B and retail landscape, refrigeration isn’t just about cooling—it’s

For many businesses in Singapore—whether you’re running a bustling restaurant, a cozy florist shop, or a convenience store—finding the right refrigeration unit is a decision that directly impacts operations. While the options seem endless, two of the most commonly used units in commercial settings are upright refrigerators and undercounter refrigerators.